Matchless Info About How To Build A Derby Car Track

Cut two long channels in the middle of the track in front of where the cars stage before the race and attach two dowels to the hinged board so that they stick up through the track when the.

How to build a derby car track. It all boils down to budget,. Purchase a tube of graphite and sprinkle a little in the wheel bore with the axle inserted part way. In this video i create the template guild bar that will be used to set the proper spacing between.

To make “fenders”, outline their shape and mark the wheel centers on 1/2 in. Four 4' lengths of pine furring strips. The slope of the track should start at 30 degrees at the starting gate, changing gradually to 0 degrees by about 12 feet from the start.

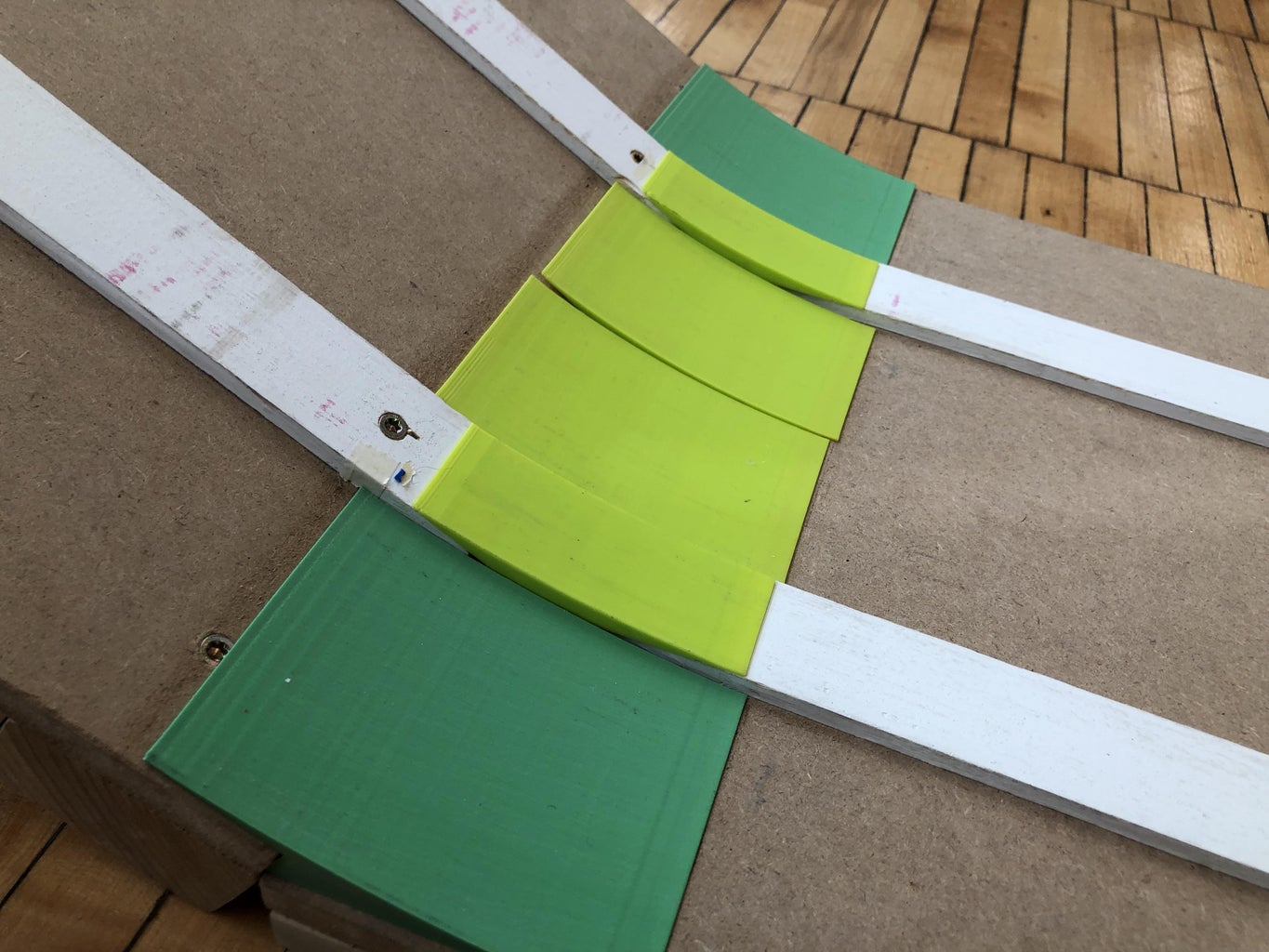

I started by making 2 identical panels for the end of the track. The track should slope from about 30 degrees at the start line changing gradually to 0 degrees about 12 feet from the start line then the track should run flat to the finish line. The track should slope from about 30 degrees at the start line.

If you cut it out with a. Be sure your car weighs as close to 5 oz as possible. The following cuts were used to create both panels:

Cut out the car/rough sand and shape it (20 minutes) depending on your method of cutting out the car will depend on whether you will shape and sand this session. Two 16 x 4' mdf panels. Find someone with a scale, purchase an inexpensive scale or weigh your car at.

When a car hits the foam pad on the stopper, the stopper is pushed to the end of track, slowing the car down within a very few inches, and making for a more gentle stop. Building your own race track can be as simple as buying a playset and some track off the shelf, or you can go hog wild and construct your own with custom parts. The heavier your car, the faster it will go.